PROTECTION OF TROLLEY AND RAILWAY LINES

The pfl system, dedicated to the protection of trolleybus and railway lines, continuously monitors the physical integrity of the contact wire of the overhead line or of the equipotential conductor.

Recognizes fault conditions in a maximum time of 200ms; and in the event of breakage, it intervenes in a maximum time of 20ms to cut off the voltage, so as to guarantee electrical safety and localization of the fault. PLF makes up for the current situation of trolleybus and tramway lines, which is characterized by a widespread lack of compliance with the main safety criteria of electrical systems.

SAFETY FIRST

The PLF system represents a decisive step forward in the sector, as it allows protection of the trolleybus line by performing the appropriate functions at the various operating levels, in compliance with the standards.

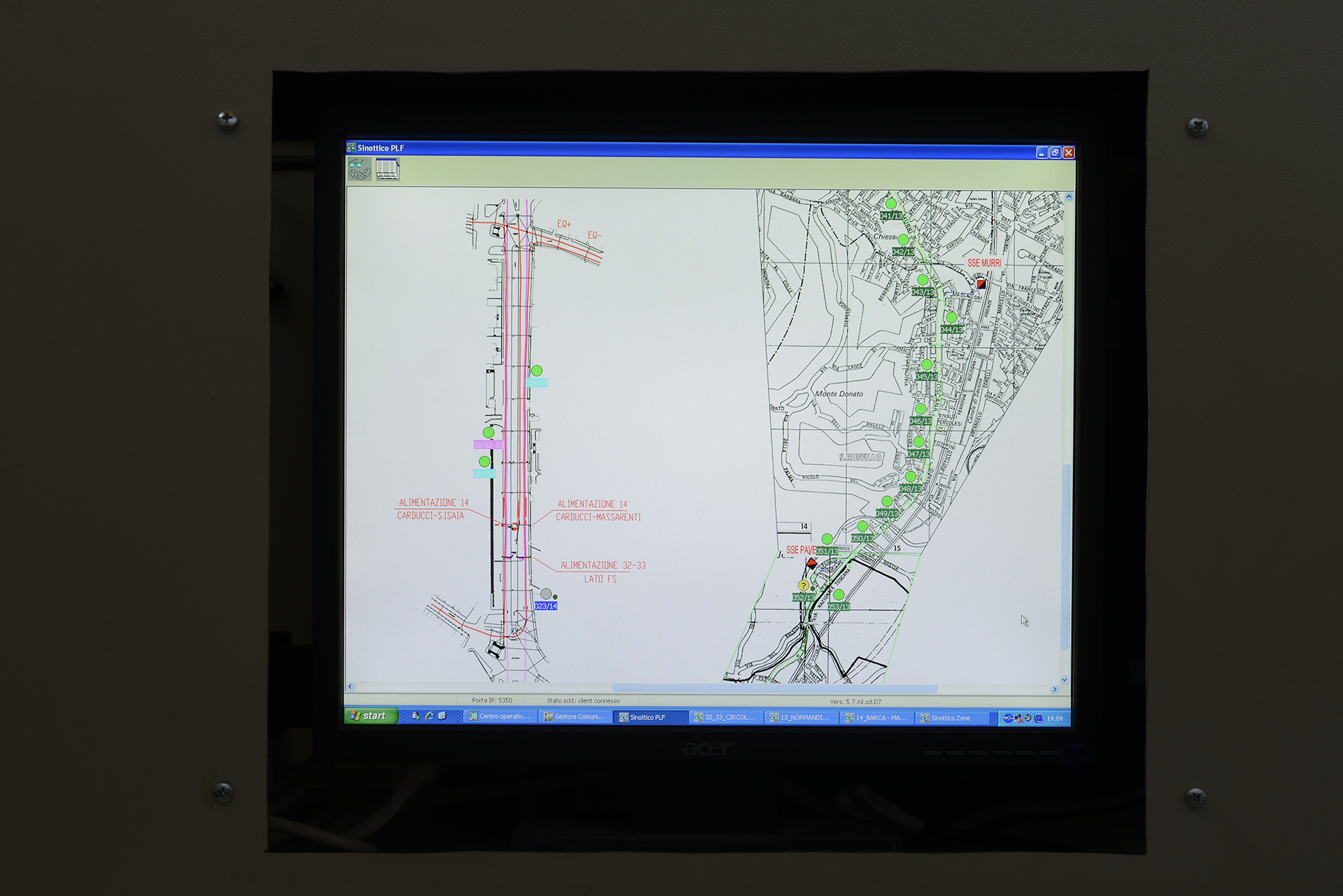

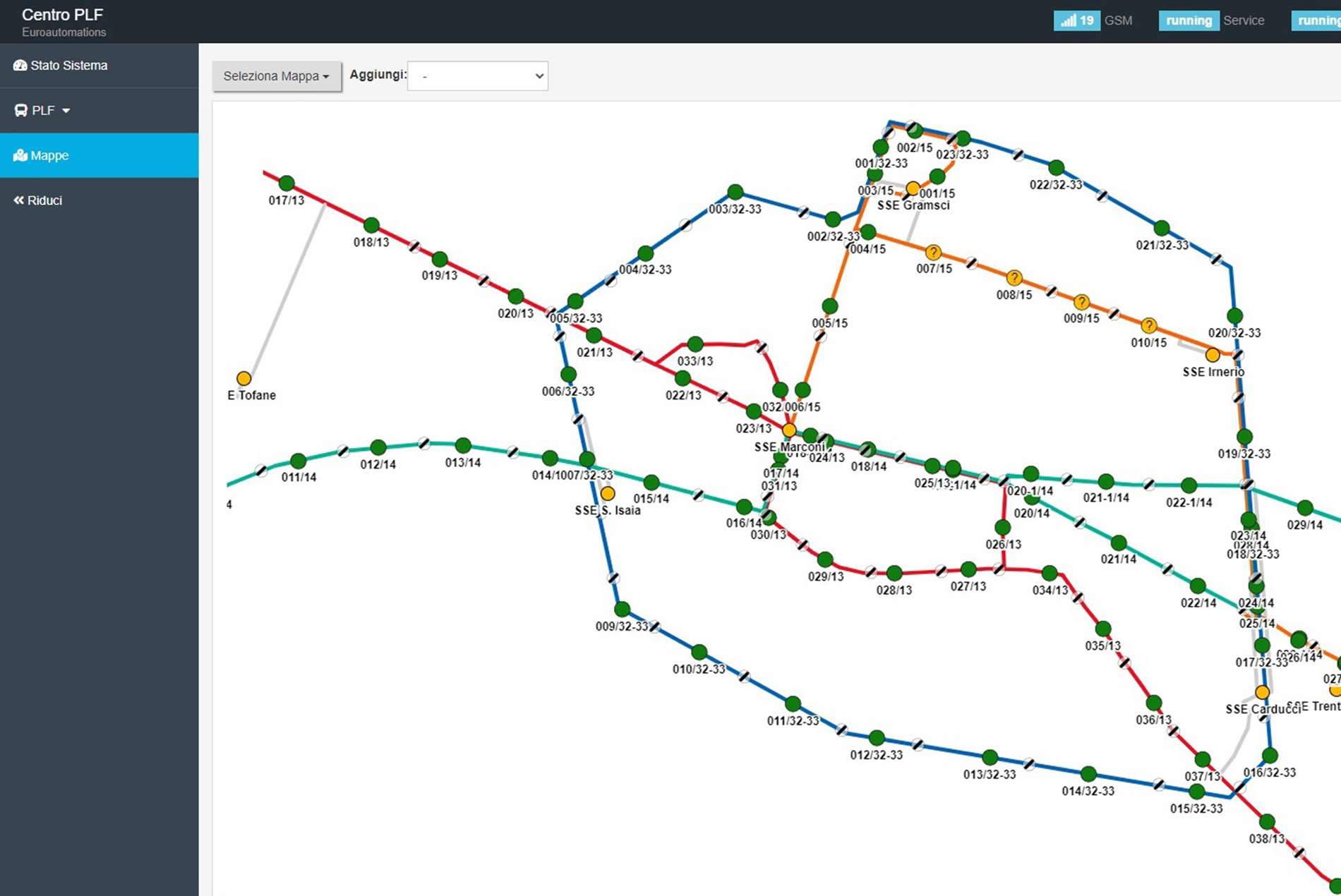

SYSTEM ARCHITECTURE

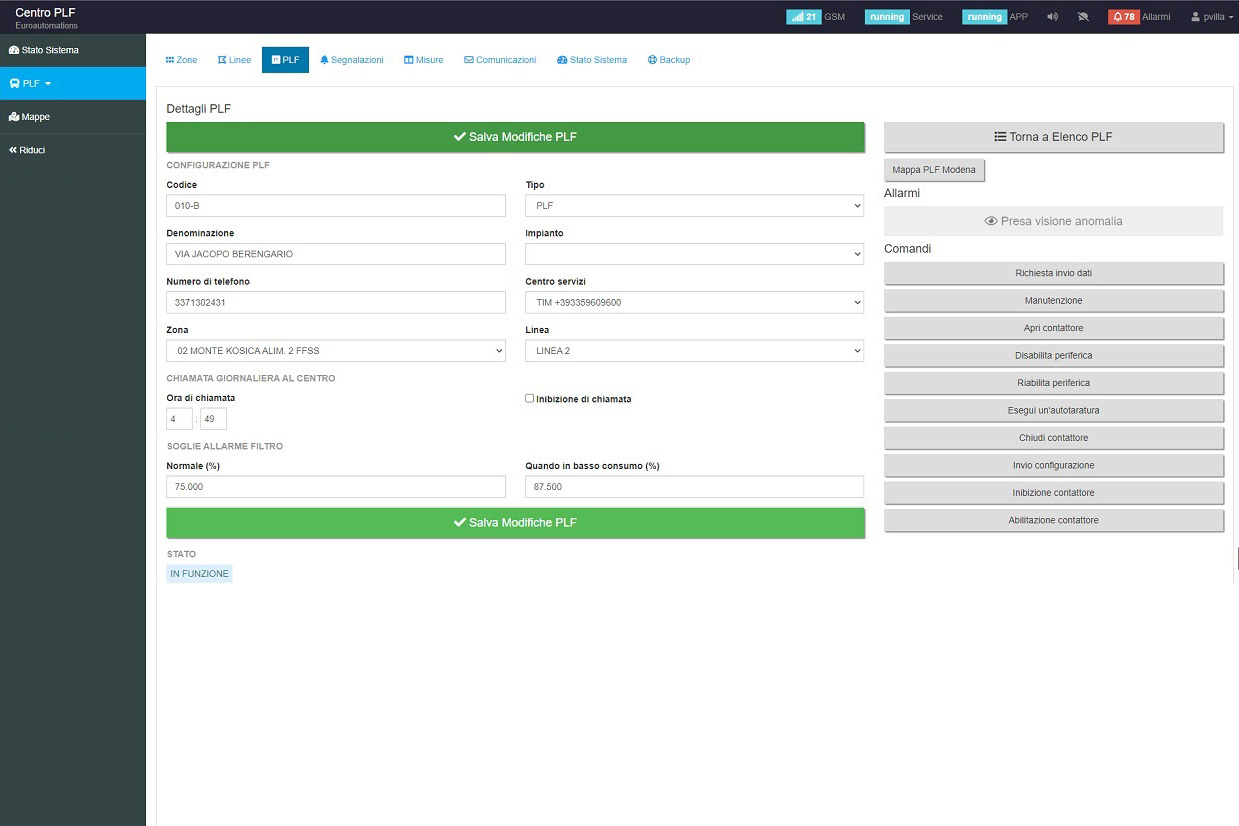

The contact wire break detection system consists of a set of peripheral surveillance devices called PLF, a Front End unit located in the SSE and an Operational Control Centre.

CONTROL DEVICE

Each peripheral PLF device operates in relation to a single line section, providing continuous monitoring of the state of the contact line to instantly detect changes in its electrical parameters.

In a maximum time of 200ms, it recognizes the onset of contact line breakage, diagnoses the type of fault and sends the opening order of the extra-rapid circuit breakers via the Front-End Units located in the relevant SSEs.

The PLF periodically performs self-diagnostics automatically with simulation of line faults, to check its efficiency.

Notify the control center of any situation

operational anomaly:

• disconnection of the PLF device from the line;

• failed simulation test;

• battery voltage out of range;

• fiber optic network out of order.

The line check is also performed under conditions of

out of voltage or temporarily out of line service,

intermittently, for a period

maximum of 5 days.

FRONT END OF SSE

The substation Front-End unit has the task of cyclically interrogating the PLFs relating to the relevant section, of collecting the measurements and the diagnostic status, of detecting any fault signals in a maximum time of 20 ms, and of instantly activate the relay for the opening of the IR, periodically sending the collected data to the Control Center.

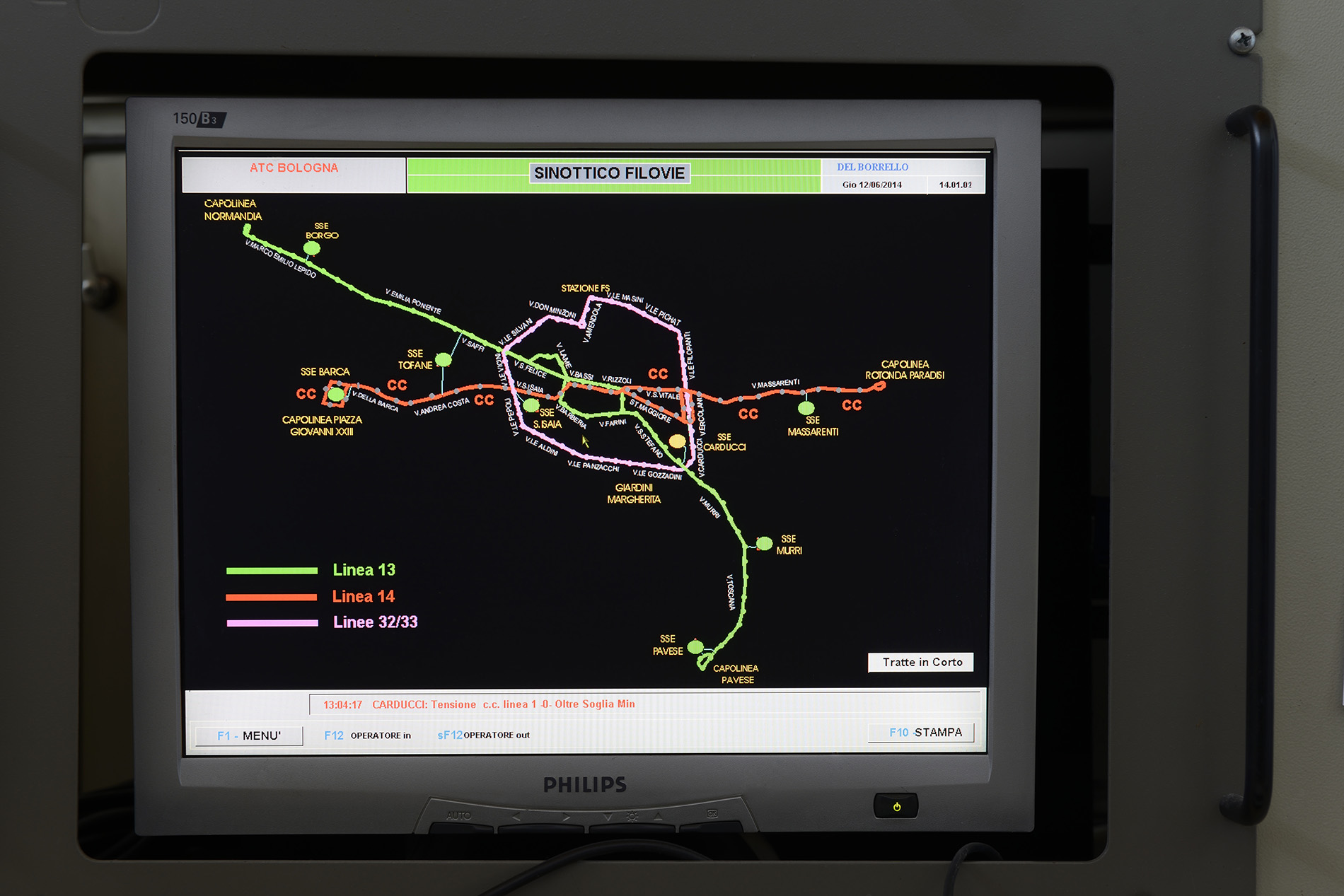

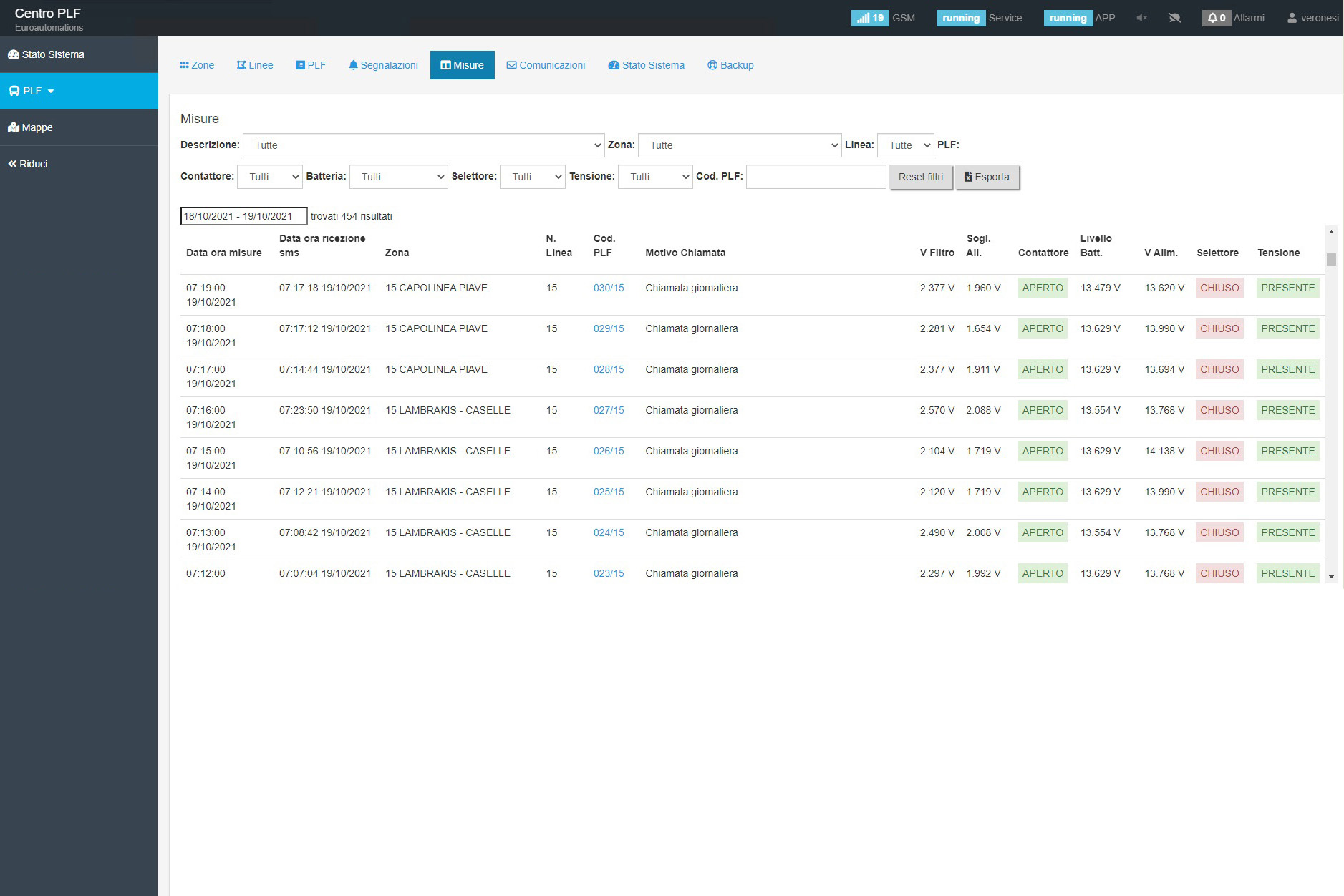

OPERATIVE CENTER

The Operations Center software manages the parameters relating to the functional and maintenance activities of the plant. It performs the following activities:

• Send to each PLF, by means of the Front-End, the

operating mode with the relative thresholds

of intervention;

• reports and logs events;

• displays test data, performed on request or automatically by PLF devices

(e.g. self-diagnosis, battery level, etc.);

• stores operating parameters and historical data;

• displays data in the form of lists (events and results of

test) and in graphic format;

• reports the status of the PLFs in via a graphical interface

line.